It has jumper pins to select either 12v Power to Motors or 5v power to motors. L293D motor driver is signaled by using a shift register 74HC595 and the shift register is signaled by using the Arduino. It has screw terminal for conncecting motors wires. This board can be controlled by using Arduino like Arduino UNO, Arduino Mega and similar boards.

This Arduino motor driver shield can be used to build DC or stepper motor based projects like a Robotic Arm, Line Follower, land robbers, maze followers and many more projects.

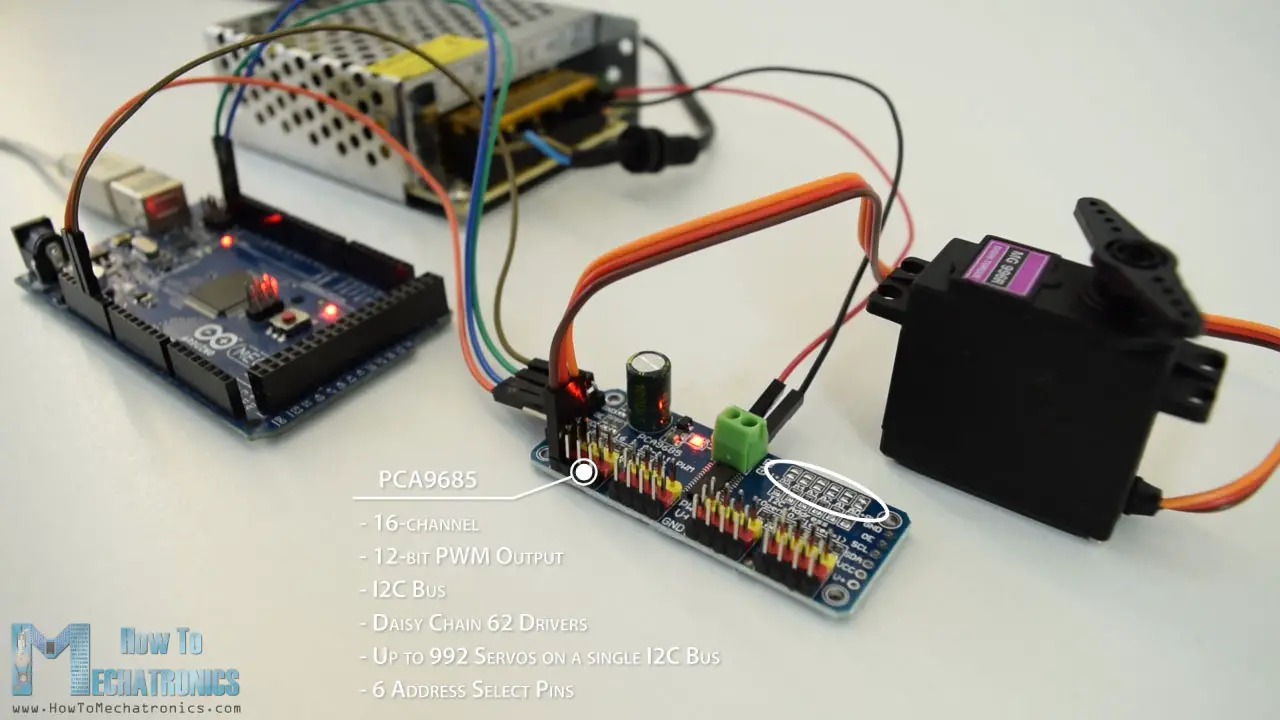

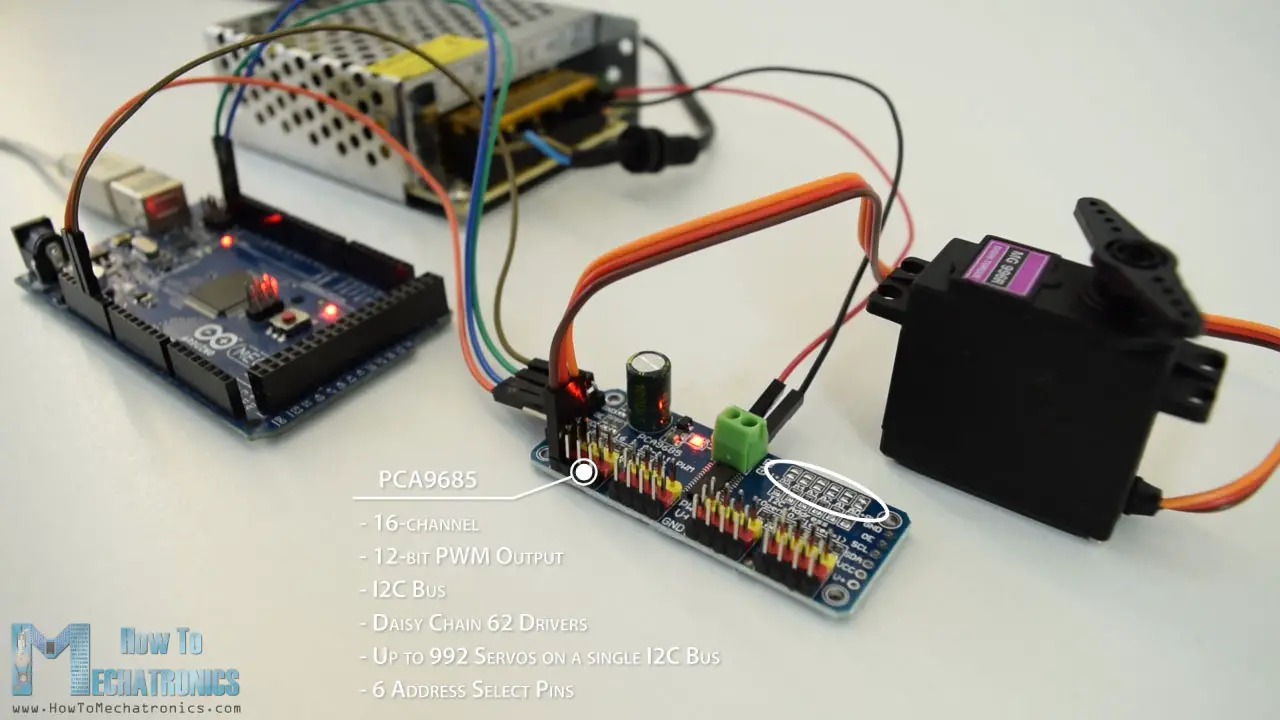

Here two L293D Motor Driver ICs are used for driving motors and an 8-bit shift register for controlling them. Compatible with Arduino UNO and Arduino Mega, this motor driver shield can operate 4 DC motors or 1 stepper motor and 2 servo motors at a time. The PWM Pins are unnecessary if you do not want to control PWM features.In this DIY session, we make an Arduino Motor Driver Shield to drive DC motors, stepper motor and Servo Motor. Make sure you have all of your grounds tied together Arduino, Power source, and the Motor Controller. H-bridges are typically used in controlling motors speed and direction but can be used for other projects such as driving the brightness of certain lighting projects such as high powered LED arrays.

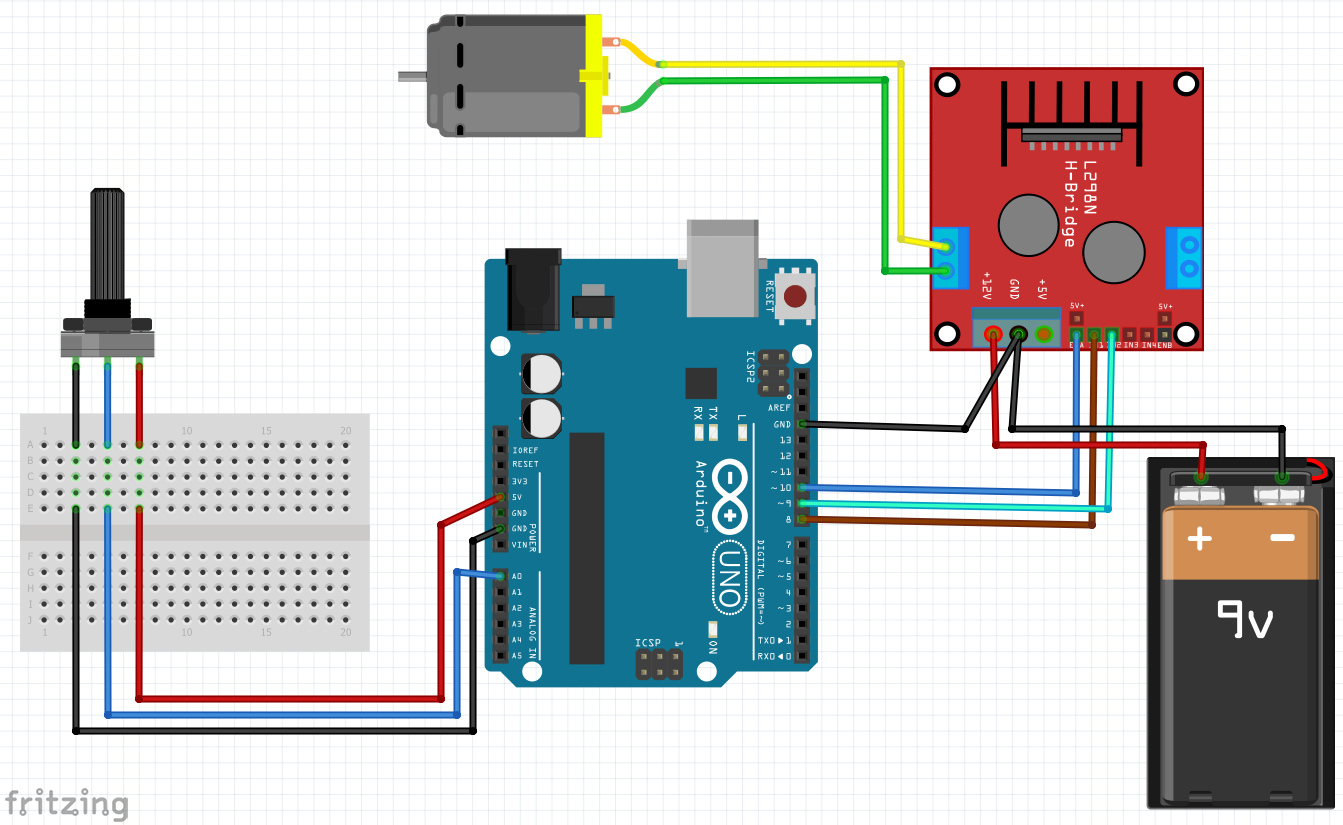

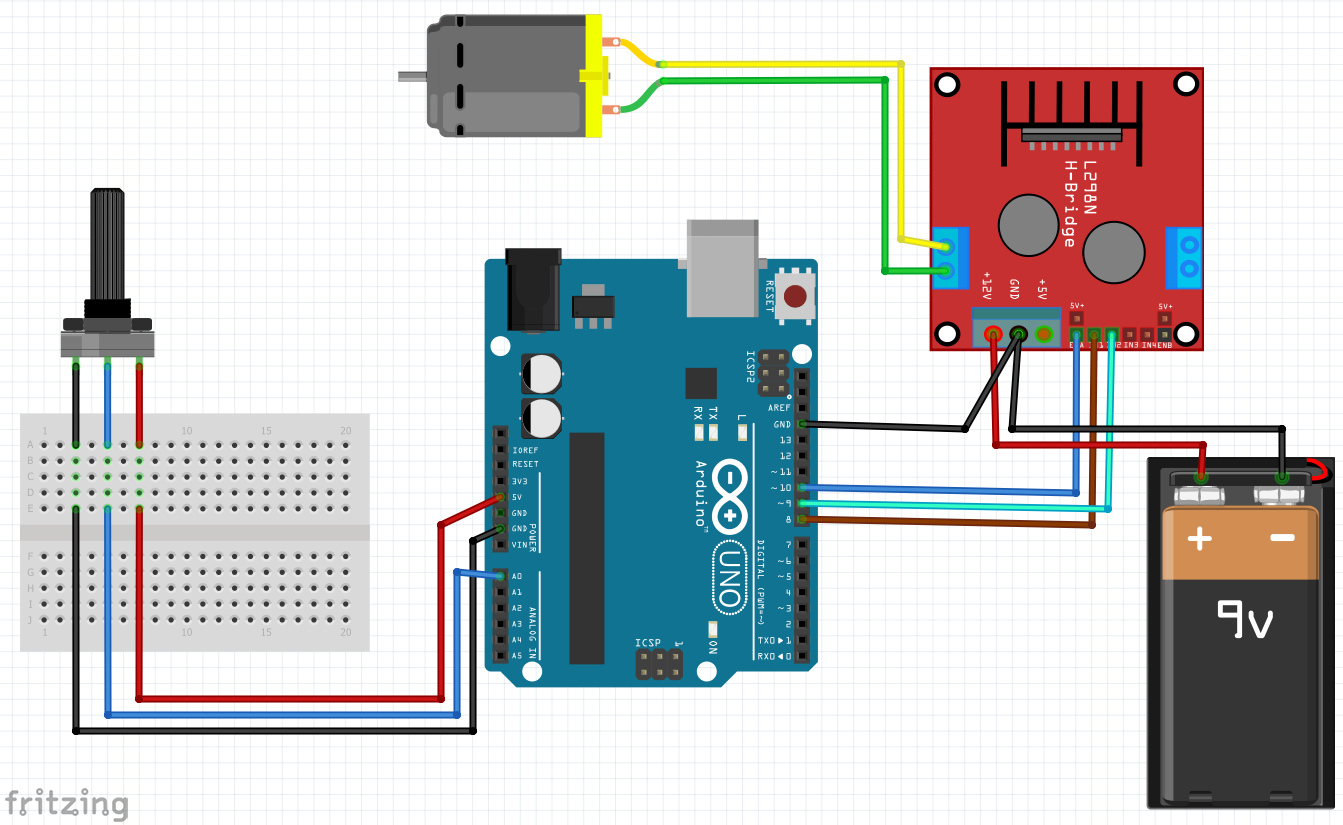

EnA: Enables PWM signal for Motor A (Please see the “Arduino Sketch Considerations” section). 5v: 5v input (unnecessary if your power source is 7v-35v, if the power source is 7v-35v then it can act as a 5v out). Out 4: Mo (Can actually be from 5v-35v, just marked as 12v). Logical part of the operating current range: 0 ~ 36mA. Logical part of the terminal power supply range Vss :4.5V-5.5V. Drive part of the peak current Io: 2A / Bridge. Driver chip: L298 dual H-bridge driver chip. Motors will last much longer and be more reliable if controlled through PWM. The longer the pulses the faster the wheel will turn, the shorter the pulses, the slower the water wheel will turn. Take the water wheel analogy and think of the water hitting it in pulses but at a constant flow. Motors are rated at certain voltages and can be damaged if the voltage is applied to heavily or if it is dropped quickly to slow the motor down. The voltage would be the water flowing over the wheel at a constant rate, the more water flowing the higher the voltage. In motors try to imagine the brush as a water wheel and electrons as the flowing droplets of water. Pulse Width Modulation is a means of controlling the duration of an electronic pulse. Perfect for driving DC and Stepper motors for micro mouse, line following robots, robot arms, etc.Īn H-Bridge is a circuit that can drive a current in either polarity and be controlled by Pulse Width Modulation (PWM). This motor driver is perfect for robotics and mechatronics projects and perfect for controlling motors from microcontrollers, switches, relays, etc. It can control up to 4 DC motors, or 2 DC motors with directional and speed control

It uses the popular L298 motor driver IC and has the onboard 5V regulator which it can supply to an external circuit. This L298 Based Motor Driver Module is a high power motor driver perfect for driving DC Motors and Stepper Motors.

0 kommentar(er)

0 kommentar(er)